+86-17717409276

This product is a non-silicon composite mineral oil defoamer,fast bubble breaking, strong foam inhibition ability, excellent microbubble elimination performance.

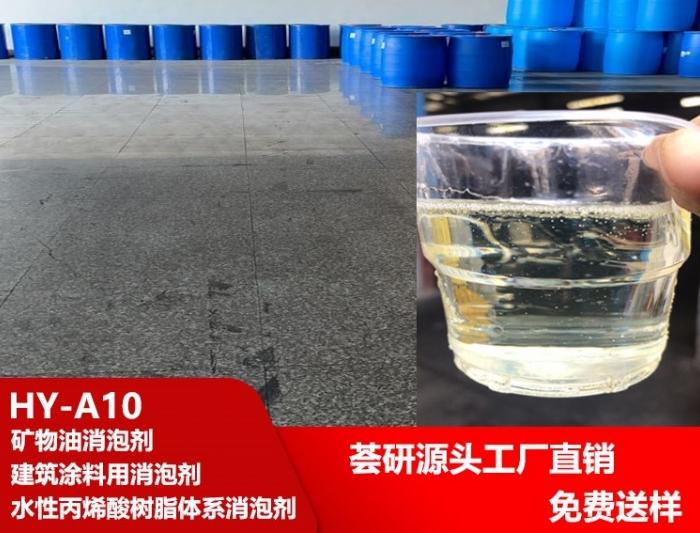

Nonionic mineral oil defoamer HY-A10

Overview:

This product is a non-silicon composite mineral oil

defoamer, containing modified mineral oil, foam-breaking molecules, and

defoaming and synergistic particles. fast bubble breaking, strong foam inhibition

ability, excellent microbubble elimination performance. It is especially

suitable for water-based industrial paints, water-based all-part paints,

architectural coatings, emulsion synthesis, etc. Good compatibility and not

easy to precipitate.

Physical indicators:

Appearance: Opaque light yellow viscous liquid

Solid content (%) : ≥98%

Stability (3000 RPM /20 min) : No stratification

Viscosity (25℃) : 1500CS-2000CS

Chemical properties:

Has good versatility, especially suitable for water-based

acrylic resin systems, water-based architectural coatings, adhesives, etc., and

is cost-effective.

Application recommendation:

Can be added as original or pre-diluent, and pre-dilution with the recommended solvent simplifies addition and mixing.

Dosage: about 0.5%, different formulas need to be experimented to

determine the best dosage. There may be a little layering when left for a long

time, and it can be shaken slightly before use without affecting the

performance of the product.

Storage packaging:

Packaging: This product is packaged in original 25/200KG barrels (can be split);

Storage: Store in a cool and sheltered place, sealed and stored;

Transportation: This product should be well sealed during transportation to prevent moisture, strong alkalis, acids, and rainwater from entering.

Additional Disclaimer: This information is based on the information and experience currently available to us. It only describes the performance of our products, but does not guarantee the performance of the products in a legal sense. It is recommended to test our products first to determine if they can achieve the desired results.