+86-17717409276

This product is a mixture of cyclic siloxane and polydimethylsiloxane crosspolymer and polydimethylsiloxane/vinyl polydimethylsiloxane crosspolymer and polydimethylsiloxanol.

Silicone elastomer HY-9050

Features:

1. Silicone elastomer gel

2. Thickening effect in water/oil, water/silicone oil system

3. Slightly sebum-absorbent

Advantages:

1. It can be processed at room temperature

2. Velvet smooth feeling, refreshing and non-greasy skin feeling

3. Enhance the beauty function of products.

4. Reduce the sticky feeling of the formula system

Overview:

This product is a mixture of cyclic siloxane and polydimethylsiloxane crosspolymer and polydimethylsiloxane/vinyl polydimethylsiloxane crosspolymer and polydimethylsiloxanol. It is a silicone elastomer gel with high transparency. The nature of its gel determines that this product does not really dissolve in any oil phase, and can only exist in the form of stable dispersion. This product can be used in a variety of cosmetic formulations such as water/oil emulsions, water/silicone oil emulsions, oil/water emulsions and anhydrous products in order to obtain a dry, velvety smooth, non-greasy skin feel. This product will be thickened after prolonged storage, and will be thinned by shear force, which is not a product quality problem.

Technical indicators:

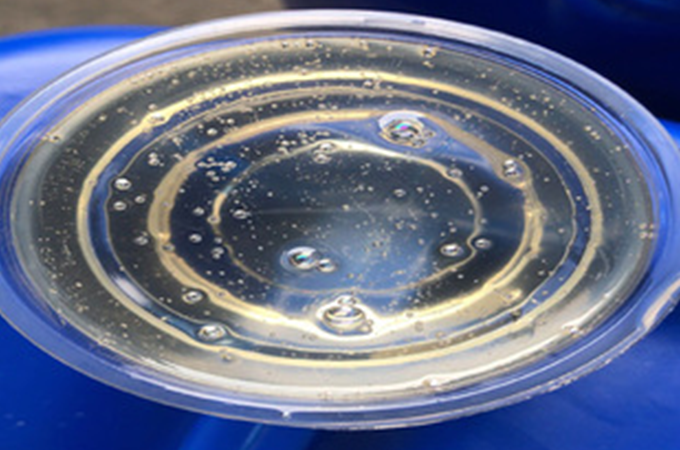

Appearance: colorless translucent colloid

Nonvolatile content (%,w/w): 14 ~ 17

Viscosity (cP, S94, 2.5RPM, 25℃): 250,000 ~ 450,000.

Application field:

Skin care, hair care and other cosmetic formulations: such as sunscreen, make-up, styling and other products.

How to use:

The product can be directly dispersed in the oil phase of the formulation (silicone oil or organic oil) and stirred, without subsequent shear processing.

In emulsion formulations, it is added directly to the oil phase or silicone oil raw material. It is recommended that the oil phase be homogenized separately prior to emulsification, or that the dispersed oil phase be slowly poured into the product with proper agitation;

If the viscosity of the whole dispersed phase can ensure the dispersion of the product, it can also be added later;

When heating operation, it should be carried out in a closed container, and the heating time should not be too long to avoid the volatilization of cyclopentadimethylsiloxane;

It is recommended that the operating temperature should not exceed 60℃ to avoid the volatilization of cyclopentadimethylsiloxane.

Recommended dosage:

The recommended dosage of this product is 1~20% (according to the total formula).

Packaging specifications:

This product is packed in 20Kg plastic drums and 200Kg iron drums.

Storage and transportation:

This product is non-hazardous.During storage and transportation, attention should be paid to moisture-proof, to prevent the mixing of acid and alkaline impurities. The container should be sealed tightly after each use. The storage period is two years under sealed and room temperature conditions.

Additional Disclaimer: This information is based on the information and experience currently available to us. It only describes the performance of our products, but does not guarantee the performance of the products in a legal sense. It is recommended to test our products first to determine if they can achieve the desired results.