+86-17717409276

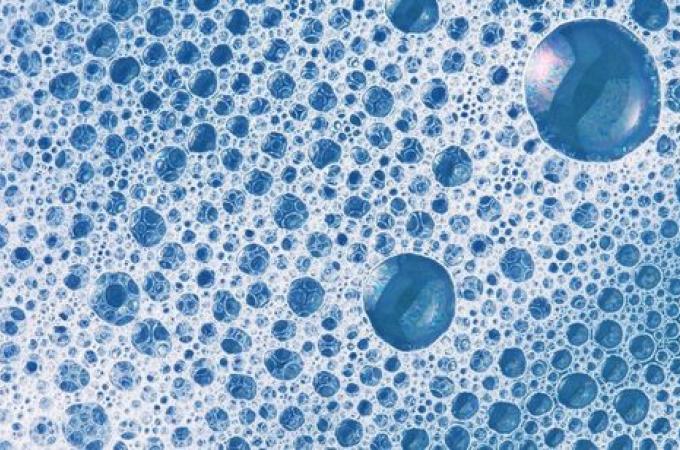

Silicone defoamer for aqueous pigment concentrates and printing inks to prevent foaming during the grinding phase.

Silicone defoamer HY-019

Product Overview:

Silicone defoamer for aqueous pigment concentrates and printing inks to prevent foaming during the grinding phase. Excellent long-term stability and shear stability. It is particularly suitable for resin-free grinding (water slurry grinding) and water-based overprint coatings.

Product physical and chemical data:

Density (20 °C): 0.98 g/ml

No volatile matter (60 min., 105 °C): 60%

Flash point: 78 °C

Fields of application:

Coating industry

Particularly suitable for water-based coating systems for polyurethane dispersions and polyurethane/acrylate composite dispersions as well as pigment concentrates. It can effectively eliminate microbubbles.

Suggested dosage: 0.1-1 % of the additive dosage (purchased form) is based on the total formulation.

Printing inks and overprint varnishes:

Suitable for aqueous overprint varnishes based on acrylic dispersions, polyurethane dispersions and polyurethane/acrylate composite dispersions, as well as for the defoaming of pigment concentrates. Effective elimination of microbubbles for both aqueous and UV systems.

Recommended dosage: 0.1-1 % Adjuvant dosage (purchased form) is based on the total formulation.

Storage and Packaging:

Packaging: This product is packaged in original 25/200KG barrels (can be split).

Storage: Store in a cool and sheltered place, tightly sealed.

Transportation: This product should be well sealed during transportation to prevent moisture, strong alkalis, acids, and rainwater from entering.

Additional Disclaimer: This information is based on the information and experience currently available to us. It only describes the performance of our products, but does not guarantee the performance of the products in a legal sense. It is recommended to test our products first to determine if they can achieve the desired results.