+86-17717409276

Solvent-free wetting and dispersing additives for solvent-borne and solvent-free coatings, adhesives, PVC plastisols and ambient curing resin systems.

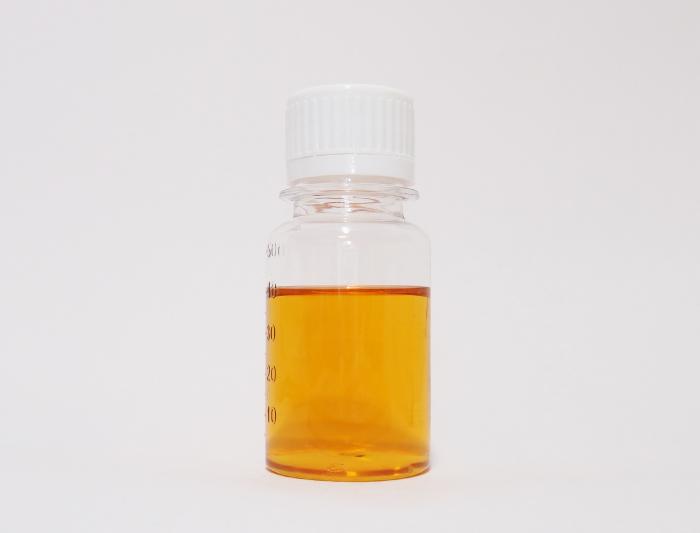

Wetting dispersant HY-9076

Overview:

Solvent-free wetting and dispersing additives for solvent-borne and solvent-free coatings, adhesives, PVC plastisols and ambient curing resin systems, as well as in the production of masterbatches for thermoplastics. It is especially recommended for carbon black pigments. Prevents phase separation and,improves fiber wetting in SMC/BMC formulations.

Technical indicators:

Amine value: 44 mg KOH/g

Acid value: 38 mg KOH/g

Density (20 °C) : 1.05 g/ml

Fields of application

Paints, adhesives, and PVC plastisol

Product Features and Benefits:

HY-9076 deflocculates pigments by steric stabilization. At the same time, it also makes the pigment particles all have the same charge, and the resulting repulsive force and steric stabilization prevent the occurrence of flocculation, so as to obtain a color appearance without blooming in a system containing multiple pigments. Due to the small particle size of the deflocculated pigments, it is possible to achieve high gloss and improve tinting strength. In addition, the transparency of transparent pigments and the hiding power of opaque pigments can be improved. Due to its viscosity reduction effect, the flow properties are improved and the amount of pigments added can be increased.

Recommended Uses:

HY-9076 is suitable for all kinds of pigments, especially recommended for stabilizing acidic and neutral carbon black pigments. It can be used for solvent-based and solvent-free coatings, adhesives and PVC plastisols. One of its important application fields is the preparation of solvent-free pigment concentrated slurry for the above applications..

Recommended dosage:

The dosage of auxiliaries (purchased form) is based on the following pigments.:

Titanium dioxide: 1-3% Inorganic pigments: 5-10%

Organic pigments: 10-25% Carbon black: 15-50%

The above recommended dosage is for reference only, and the optimal dosage needs to be determined through a series of tests. In order to achieve the best performance of the additive, the additive must be added to the abrasive before the pigment is added.

SMC and Pultrusion process

Product Features and Benefits::

HY-9076 can prevent the phase separation of different thermoplastics in various unsaturated polyesters, and is also suitable for low volatile formulations. Recommended for stabilizing organic pigments, especially acidic and neutral carbon blacks, and for wetting carbon fibers.

Recommended dosage:

5-30% additive dosage (purchased form) is based on organic pigments and carbon black and is used to stabilize the pigment.

0.5-1% additive dosage (purchased form) is based on fiber content and is used to wet carbon fibers.

0.5-1% additive dosage (purchased form) is based on fiber content and is used to wet carbon fibers.

The above recommended dosage is for reference only, and the optimal dosage needs to be determined through a series of tests. The additive should be added to the resin mixture prior to mixing and adding solids.

Room temperature curing resin system

Product Features and Benefits:

HY-9076 flocculates the pigment by steric stabilization. At the same time, it can also make the pigment particles have the same charge, and the generated repulsive force and steric hindrance stability prevent flocculation, thus obtaining a color appearance without blooming in a system containing multiple pigments. Because the particle size of the deflocculated pigment is very small, it can obtain high gloss and improve the coloring power. In addition, the transparency of transparent pigments and the hiding power of opaque pigments can also be improved. Because of its viscosity reduction effect, the fluidity is improved and the amount of pigment added can be increased. HY-9076 is suitable for all kinds of pigments, especially recommended for stabilizing acidic and neutral carbon black pigments. It can also be used to improve the wettability of carbon fiber and make the processing reliability higher.

Suggested dosage and usage method:

The 0.5-1 % additive dosage (purchased form) is based on the filler and is used for wetting and dispersing

0.25-1% additive dosage (purchased form) is based on resin, which is used to stabilize viscosity in BMC.

The above recommended additive amount is for reference only, and the excellent additive amount needs to be determined by a series of tests.

Storage and transport separation or turbidity may occur. If there is delamination or turbidity, please heat to 30-40 degrees Celsius before use, stir well, and do not affect the use effect.

Packing and storage requirements: 25kg iron drum, 200kg iron drum. Sealed storage, storage period at room temperature for 24 months.

Additional Disclaimer: This information is based on the information and experience currently available to us. It only describes the performance of our products, but does not guarantee the performance of the products in a legal sense. It is recommended to test our products first to determine if they can achieve the desired results.